The Importance of Cell Line Development in Biotechnology

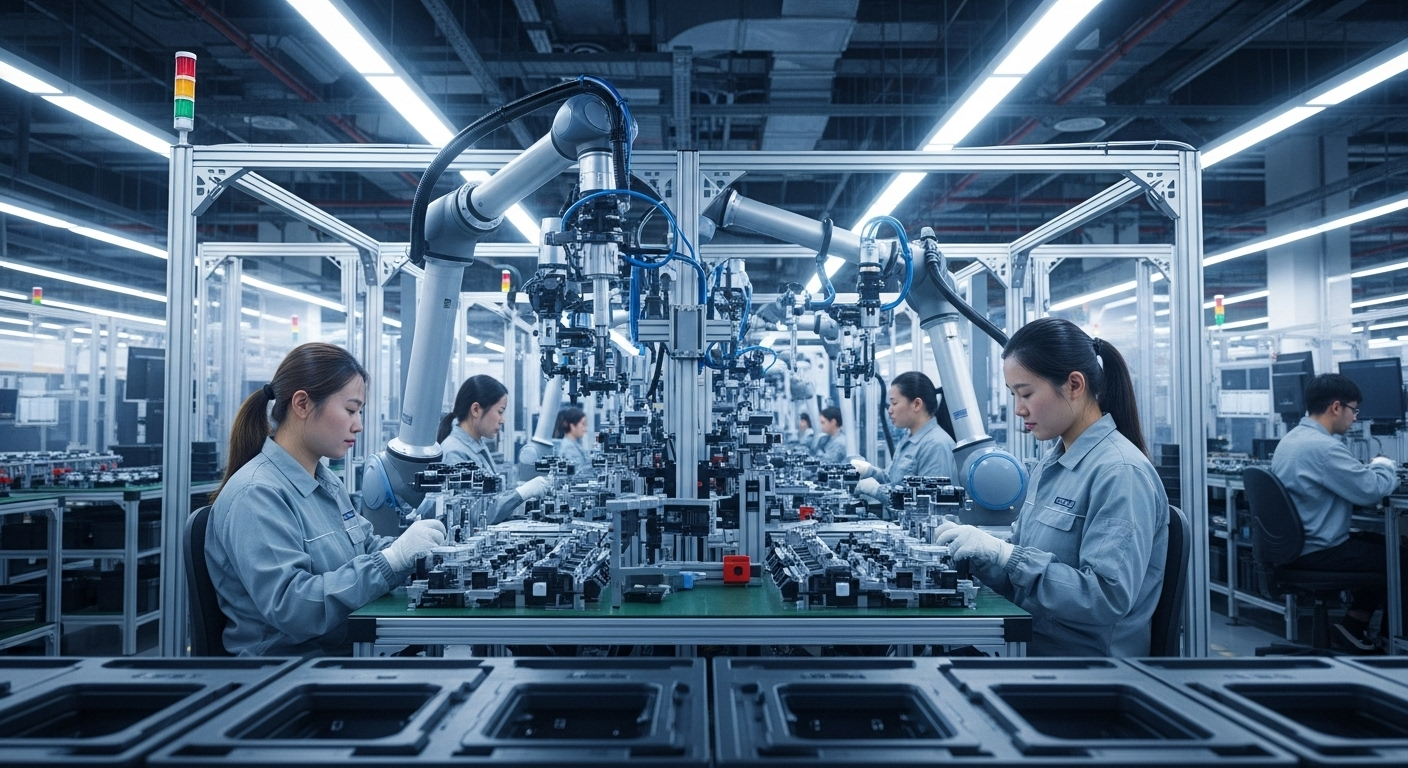

Cell line development is a cornerstone of modern biotechnology, playing a vital role in the production of biopharmaceuticals, vaccines, and therapeutic proteins. By creating stable and high-yielding cell lines, scientists can ensure consistent, scalable, and cost-effective manufacturing of biologics. This process not only supports drug discovery and development but also enhances product quality, safety, and regulatory compliance—making it an essential step in advancing healthcare and biotechnological innovation.

Cell line development represents one of the most critical processes in biotechnology, serving as the backbone for producing therapeutic proteins, vaccines, and other biological products. These carefully engineered cellular systems provide researchers and manufacturers with reliable, reproducible platforms for creating complex biological molecules that cannot be synthesized through traditional chemical methods.

The biotechnology industry relies heavily on stable cell lines to manufacture everything from insulin and growth hormones to sophisticated cancer treatments and viral vaccines. Without robust cell line development capabilities, many of today’s breakthrough therapies would simply not exist. The process requires extensive expertise in molecular biology, cell culture techniques, and quality control systems to ensure consistent and safe production.

Understanding the Process of Cell Line Development

The process of cell line development begins with selecting an appropriate host cell type, typically mammalian cells like Chinese Hamster Ovary (CHO) cells or Human Embryonic Kidney (HEK) cells. Scientists then introduce genetic material encoding the desired protein through various transfection methods, including electroporation or viral vectors.

Once transfected, cells undergo rigorous screening to identify those producing the highest levels of the target protein. This selection process often involves multiple rounds of cloning and testing, where individual cells are isolated and expanded into colonies. Researchers evaluate each clone for protein expression levels, growth characteristics, and genetic stability.

The development timeline typically spans several months, involving clone selection, characterization, and optimization of culture conditions. Throughout this process, scientists must maintain sterile conditions and carefully monitor cell viability, ensuring the selected cell line can consistently produce the desired product over extended periods.

Applications in Biopharmaceutical Production

Applications in biopharmaceutical production demonstrate the versatility and importance of cell line development across multiple therapeutic areas. Monoclonal antibodies, which represent the largest segment of biopharmaceutical products, rely entirely on engineered cell lines for commercial production. These antibodies treat conditions ranging from cancer and autoimmune diseases to infectious diseases.

Recombinant proteins constitute another major application area, with cell lines producing insulin, growth factors, enzymes, and blood clotting factors. Vaccine production also depends heavily on cell line technology, particularly for viral vaccines where cells serve as hosts for virus replication or for producing viral proteins that trigger immune responses.

Gene therapy applications increasingly utilize cell lines to produce viral vectors that deliver therapeutic genes to patients. Additionally, cell lines support the production of biosimilars, providing cost-effective alternatives to expensive branded biologics while maintaining equivalent safety and efficacy profiles.

Challenges and Future Prospects in Cell Line Development

Challenges and future prospects in cell line development reflect both current limitations and emerging opportunities in the field. One primary challenge involves achieving consistent protein quality and quantity across different production batches. Genetic instability can lead to decreased productivity over time, requiring continuous monitoring and potential re-engineering of cell lines.

Regulatory compliance presents another significant challenge, as cell lines used for therapeutic production must meet stringent safety and quality standards. Documentation requirements, contamination control, and validation processes add complexity and cost to development programs.

Future prospects include advances in synthetic biology and genome editing technologies like CRISPR, which enable more precise modifications to cell lines. These tools allow scientists to enhance protein production, improve cell growth characteristics, and reduce development timelines. Artificial intelligence and machine learning are also being integrated to optimize culture conditions and predict cell line performance.

Cost Considerations in Cell Line Development

Cell line development involves substantial financial investment, with costs varying significantly based on project complexity and timeline requirements. Basic cell line development projects typically range from $50,000 to $200,000, while more complex programs involving multiple clones and extensive characterization can exceed $500,000.

Development timelines directly impact costs, with standard projects requiring 6-12 months and expedited programs commanding premium pricing. Specialized services like glycoengineering or difficult-to-express proteins often carry additional charges of 20-50% above standard rates.

| Service Type | Provider Example | Cost Estimation | Timeline |

|---|---|---|---|

| Basic CHO Cell Line | Lonza Biologics | $75,000-$150,000 | 6-9 months |

| Stable Pool Development | Catalent | $30,000-$80,000 | 3-6 months |

| Single Clone Selection | WuXi Biologics | $100,000-$250,000 | 8-12 months |

| Glycoengineered Lines | Samsung Biologics | $200,000-$400,000 | 10-15 months |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Quality Control and Regulatory Considerations

Quality control measures throughout cell line development ensure product safety and regulatory compliance. Testing protocols include genetic stability assessments, adventitious agent screening, and comprehensive characterization of protein products. These quality systems add time and cost to development programs but remain essential for regulatory approval.

Regulatory agencies like the FDA and EMA require extensive documentation of cell line history, including origin, modifications, and testing results. Master Cell Banks and Working Cell Banks must be established under Good Manufacturing Practice conditions, with detailed records maintained throughout the cell line lifecycle.

Cell line development continues to evolve as biotechnology advances, driving innovation in therapeutic production and enabling new treatment possibilities. The field’s importance will only grow as personalized medicine and complex biologics become increasingly prevalent in healthcare. Success in this area requires balancing scientific innovation with regulatory compliance, cost management, and quality assurance to deliver safe, effective therapeutic products to patients worldwide.